MBA (in progress), BS Life Science, Electrical Engineering

10 Years of Experience leading highly technical teams in the Army.

We’re building an advanced ultrasonic inspection and imaging system, designed for versatility across various object shapes. It integrates both hardware and software components, leveraging a flexible array technology. This system captures data from ultrasonic transducer signals transmitted across the flexible array’s elements, which can be arranged in any configuration. It uniquely features an automatic detection mechanism for pinpointing the precise locations of each ultrasonic element within the array, ensuring accurate imaging regardless of the object’s surface topology.

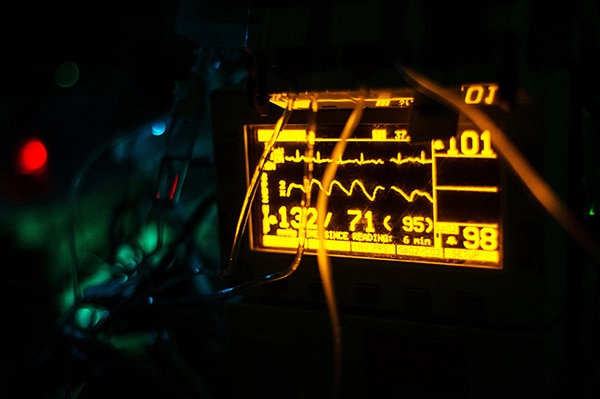

Traditional ultrasound systems, prevalent in medical imaging and Non-Destructive Evaluation (NDE), utilize arrays of ultrasound source/receiver elements mounted on a rigid substrate. This rigid backing ensures that the ultrasonic wave-field is generated and received from specific, predetermined locations, a critical requirement for accurate imaging. This necessity for fixed element positioning has historically limited the application of flexible ultrasonic arrays, confining their use to niche scenarios.

Our advanced imaging technology provides a ground breaking perspective on the human body.

MBA (in progress), BS Life Science, Electrical Engineering

10 Years of Experience leading highly technical teams in the Army.

MS Cyber Security (in progress), MS Information Systems; 20 years of experience in science-centric PR and Information Technology at New York University

Bioengineer with over 5 years experience developing bioelectronic therapies in academia and industry.

20+ years of technology development, Medical device commercialization, Project Management and Business Development

Trauma Surgeon; Navy Veteran

PhD Candidate, Vanderbilt University, focused on ultrasound imaging algorithms.